2025 Top Thermal Conductivity Meter Guide for Optimal Performance and Accuracy

In the ever-evolving landscape of materials testing, the importance of accurate and efficient measurement techniques has become more pronounced than ever. The "2025 Top Thermal Conductivity Meter Guide for Optimal Performance and Accuracy" delves into the advancements and key features of the leading thermal conductivity meters available today. According to the latest market report by Research and Markets, the thermal conductivity meter industry is projected to expand at a CAGR of 6.8% from 2023 to 2028, driven by rising demand for quality assurance across various sectors, including aerospace, automotive, and energy management.

Experts, such as Dr. Emily Chen, a distinguished figure in thermal analysis technology, emphasize the critical role of precision in this field. Dr. Chen noted, "A reliable thermal conductivity meter can significantly enhance the accuracy of your thermal testing processes, leading to better product performance and compliance." By understanding the key attributes that define the top thermal conductivity meters of 2025, users can ensure they are equipped with the technology necessary for effective thermal management and material evaluation, ultimately fostering innovation and excellence within their industries.

Top Thermal Conductivity Meters of 2025: A Comprehensive Overview

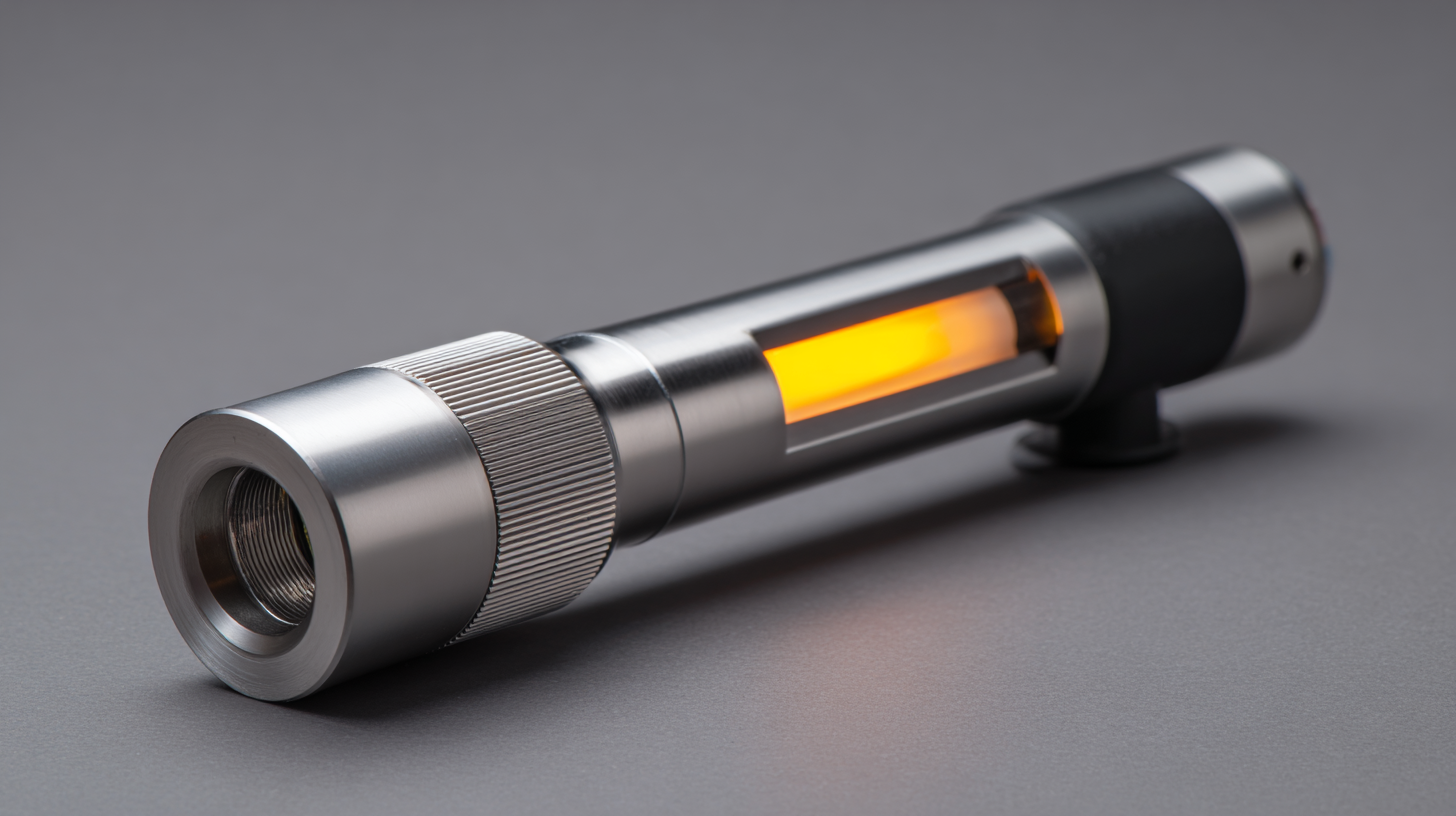

In 2025, the market for thermal conductivity meters is marked by significant advancements aimed at improving accuracy and efficiency. The latest models feature cutting-edge technology such as laser-based measurements and enhanced data logging capabilities. These innovations ensure that users can obtain precise readings quickly, making them essential tools for a variety of industries, including manufacturing, construction, and environmental research.

The top thermal conductivity meters of 2025 are designed with user-friendliness in mind, offering intuitive interfaces and robust connectivity options. Many of these devices support mobile applications that allow users to monitor and record data remotely. Additionally, advancements in materials science have led to meters that can withstand harsher environments, thus broadening their applicability. As professionals seek reliable and efficient solutions, the best thermal conductivity meters of 2025 stand out for their performance, making them vital assets for those requiring optimal accuracy in thermal conductivity measurement.

Key Features to Look for in a Thermal Conductivity Meter

When selecting a thermal conductivity meter, it’s crucial to understand the key features that enhance performance and accuracy. One essential aspect is the measurement range of the device. High-performance meters should be capable of measuring a wide variety of materials, from solids to liquids and even gels. This versatility ensures that the meter can be employed in diverse applications, including those involving extreme temperatures, such as in nanostructured thermal barrier coatings and carbon nanostructures.

Another important feature to consider is the precision of the meter. Innovations in thermal conductivity testing allow for rapid and accurate assessments, which are vital in sectors like construction and materials science. For instance, advanced methods have been developed that utilize optical fiber temperature sensors to evaluate the thermal behavior of materials, aiding in applications like ground source heat pumps.

Tips: When choosing a thermal conductivity meter, look for models equipped with modern sensors that provide real-time data. Also, consider the ease of use and portability of the device, as these features can greatly enhance productivity, especially in field tests. Always prioritize meters that offer robust calibration options to ensure continued accuracy in varying environmental conditions.

Accuracy and Performance: How to Evaluate Your Meter Choices

When evaluating thermal conductivity meters, accuracy and performance are paramount. According to a recent report from the International Journal of Thermal Analysis, the precision of thermal conductivity measurements can vary significantly between different meter models.

High-end meters boast accuracy levels as high as ±0.5%, while more economical options may only achieve ±5%. This disparity can drastically affect applications ranging from material science research to quality control in manufacturing.

Performance metrics, such as measurement speed and ease of use, are equally important. A study published in the Journal of Materials Science highlighted that meters with rapid response times, typically less than 10 seconds, are preferred in industrial settings to minimize downtime. Furthermore, user-friendly interfaces that allow for quick calibration and real-time data analysis can enhance overall operational efficiency. Whether you’re in a laboratory or a production line, selecting a meter that balances these performance criteria with precise measurements ensures optimal results for your thermal conductivity testing needs.

Best Practices for Using Thermal Conductivity Meters Effectively

When utilizing thermal conductivity meters, adhering to best practices is essential for ensuring optimal performance and accuracy. First and foremost, proper calibration of the meter before each use cannot be overstated. Regular calibration against known standards mitigates potential discrepancies in measurement, allowing for reliable data collection. It’s also advisable to utilize the recommended calibration intervals specified by manufacturers to keep equipment functioning at its best.

Additionally, the environment in which the thermal conductivity meter is used plays a crucial role in the precision of measurements. Maintaining a stable temperature and humidity level in the testing area helps prevent external factors from skewing results. Users should also ensure that the sample is adequately prepared; any surface contaminants or irregularities can lead to inaccurate readings. Furthermore, consistent technique during measurement—such as how the probe is inserted or how long it remains in the sample—contributes significantly to reliable thermal conductivity values. By following these best practices, users can significantly enhance the accuracy and effectiveness of their thermal conductivity measurements.

Comparative Analysis of the Top 5 Thermal Conductivity Meters of 2025

In 2025, the market for thermal conductivity meters has grown significantly, driven by advancements in technology and increasing demands for accuracy in various applications. A comparative analysis of the top five thermal conductivity meters reveals key differences in performance metrics such as sensitivity, response time, and the versatility of use in diverse environments. These devices are essential for measuring thermal properties in industries ranging from building materials, where thermal performance is critical, to food processing sectors that require precise thermal measurements for quality control.

Recent studies highlight the importance of understanding thermal behaviors in various materials, such as the drying kinetics of agricultural by-products or the thermal efficiency of innovative building materials. For example, exploring the thermal properties of pomegranate peels during drying processes showcases how thermal conductivity meters can assist in preserving bioactive compounds while minimizing waste.

Additionally, analyses related to the thermal performance of nanofluids, such as Behran oil-based solutions, demonstrate how advanced materials can benefit from accurate thermal assessments. As such, investing in the best thermal conductivity meters not only enhances research quality but plays a crucial role in optimizing processes across several industries, emphasizing the need for robust comparative analyses to guide investments.

Related Posts

-

Ultimate Guide to Understanding Thermal Conductivity Testing for Global Procurement Success

-

7 Key Reasons Thermal Conductivity Testing is Essential for Modern Manufacturing Success

-

How to Choose the Right Equipment for Thermal Conductivity Testing

-

How to Choose the Right Thermal Conductivity Meter for Your Application

-

Understanding Thermal Conductivity Testing for Enhanced Material Performance

-

Ultimate Guide to Mastering Thermal Conductivity Sensors for Enhanced Performance