Top 10 Heat Flux Meters for Accurate Measurements?

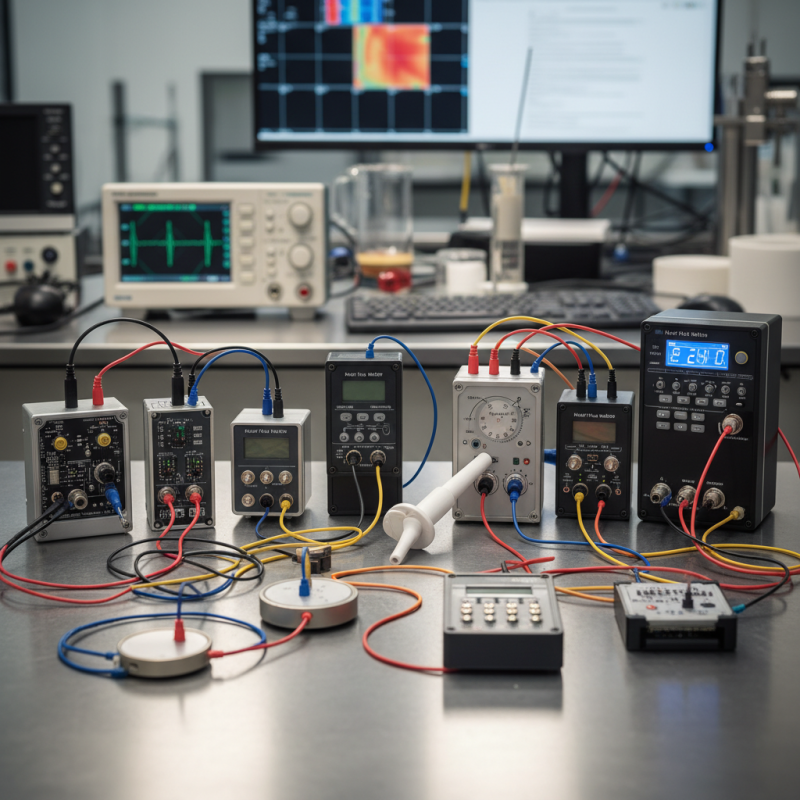

Accurate heat measurements are essential in various industries. A heat flux meter is a key tool for these applications. It measures the rate of heat transfer through a given surface area. This device is necessary for researchers and engineers. They need reliable data for product development and efficiency testing.

In selecting a heat flux meter, specific features enhance accuracy. Sensitivity, range, and temperature limits are crucial. Some models may have advanced features, like data logging and real-time monitoring. However, not all options provide consistent results. Users may encounter discrepancies between readings. Such variations prompt further consideration about device calibration and environmental factors.

Understanding your needs is important when choosing a heat flux meter. The right meter can greatly impact project outcomes. Misleading data can lead to poor decision-making and costly errors. Evaluating the top ten models available can provide useful insights. Take time to assess what works best for your specific requirements.

Overview of Heat Flux Meter Technology

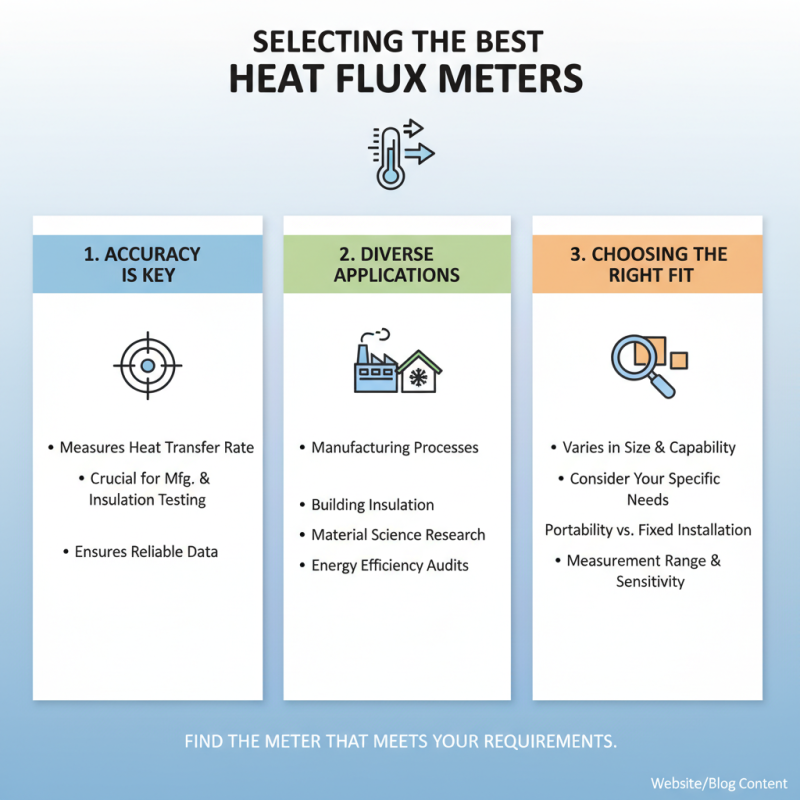

Heat flux meters play a vital role in measuring thermal energy transfer. These devices capture the rate of heat flow through a surface. They are crucial in various applications, such as building insulation, HVAC systems, and material research. Understanding heat flux meter technology helps users select the right tool for their needs.

The core principle behind heat flux meters involves the use of sensors that detect temperature differences. Such sensors are typically mounted onto surfaces to measure heat transfer dynamics. Different designs exist, including thin-film sensors and thermopile devices. Each has unique features impacting accuracy and response time. Users often face challenges in calibration, which can lead to inconsistent readings if not managed properly.

Environmental factors also affect measurements. A heat flux meter may deliver varying results depending on ambient conditions. For instance, drafts in a room or surface irregularities can skew data. Recognizing these variables is essential. Users should consider potential errors and calibrate their devices frequently. This proactive approach can improve measurement accuracy. Understanding these nuances is critical for anyone relying on heat flux measurement in their work.

Top 10 Heat Flux Meters for Accurate Measurements

This chart displays the heat flux measurements in watts per square meter (W/m²) for ten different heat flux meter models. Accurate heat flux measurement is essential in various industrial and laboratory applications.

Key Features to Consider When Choosing a Heat Flux Meter

When selecting a heat flux meter, precision is crucial. Look for models that offer reliable accuracy in measurements. Different applications may require varying levels of sensitivity. Some meters are designed for specific environments, like laboratory settings or field studies. Make sure to assess the range of measurements available.

User-friendliness can enhance the measurement experience. A clear display and straightforward interface are beneficial. Some devices provide real-time data, which is a game-changer. Consider how easy it is to calibrate and maintain the device. Batteries or charging options can impact usability too. Check if the device is lightweight for portability.

Integration capabilities also matter. Ensure that the meter can connect to other devices or software. This feature can aid in data analysis and interpretation. Some models may support data logging and sharing, enhancing their functionality. Always think about your specific needs and situations. An ideal meter should not only fit your requirements but also adapt to future changes.

Top 10 Best Heat Flux Meters on the Market

When selecting the best heat flux meters, accuracy is paramount. These tools measure heat transfer rates, crucial for various applications like manufacturing and insulation testing. Effective models can vary in size and capability. It's essential to find one that fits your specific needs.

Consider the calibration process when choosing a heat flux meter. Calibration affects accuracy directly. Some models require frequent recalibration, while others claim long-term stability. Keep an eye on maintenance requirements. A poorly maintained meter can yield misleading results.

**Tip:** Look for meters with clear user interfaces. This feature can simplify data interpretation. Sometimes, user-friendliness gets overlooked. An intuitive meter may save time and frustration during data collection.

Evaluate the features offered by the meters you consider. Some come with data logging capabilities, while others focus solely on live readings. Reflect on what aspects are most valuable to you. A more complex device isn’t always better.

**Tip:** Don't underestimate portability. If you need to take measurements in various locations, weight and ease of transport matter. You don’t want a cumbersome device slowing you down.

Think about sensor sensitivity as well. A meter that captures small fluctuations will provide more detailed information. Understand your project requirements, and choose wisely. Sometimes, the most expensive option isn't necessary for your situation.

Detailed Reviews of Each Featured Heat Flux Meter

When evaluating heat flux meters, the focus should be on their accuracy and reliability. A good heat flux meter captures vital data on thermal exchanges. Some models feature advanced sensors, which can enhance measurement precision. Look for devices that offer real-time monitoring. This can help in field applications where immediate feedback is crucial. The interface also matters; intuitive displays allow for easier setup and adjustments on the go.

Reading reviews helps in understanding different models’ strengths and weaknesses. Some heat flux meters perform well but may struggle with specific conditions. User experiences often highlight these insights. A meter that works perfectly indoors might not provide the same results outdoors. Consider the environment where the device will be used. Additionally, pay attention to calibration requirements. Regular calibration ensures ongoing accuracy, but it is an additional task some users may overlook.

Heat flux meters come with varying features. Some include data logging capabilities, while others focus solely on real-time measurement. Assessing what features are most relevant for your needs is essential. Some meters may have complex settings, which can be overwhelming. Finding a balance between functionality and usability is key. Also, think about the long-term support that comes with the device. Some users may regret a hasty choice when they encounter issues later.

Applications and Use Cases for Heat Flux Meters

Heat flux meters are essential tools in various applications. They measure heat transfer rates accurately, aiding in research and industry processes. In construction, these meters help evaluate energy efficiency in buildings. Engineers can pinpoint thermal insulations' effectiveness and ensure materials meet standards. It's a game-changer for designers and builders alike.

In research laboratories, heat flux meters play a crucial role. Scientists use them in thermal studies to understand heat distribution in materials. This information is vital for industries like aerospace and automotive, where temperature control is key. The precise data can lead to better product designs and enhanced safety features.

Tip: Calibration matters. Regularly check the calibration of your heat flux meter for optimal performance.

Another application is in renewable energy. Heat flux meters assess solar panels' efficiency. They help in fine-tuning systems for maximum energy conversion. Monitoring surface temperatures also aids in geothermal studies. Understanding the thermal properties of soils can lead to more successful installation techniques.

Tip: Always consider environmental conditions. Temperature and humidity can affect readings. Adjust your methods accordingly to ensure accurate data.

Keep in mind that while heat flux meters are powerful, they have limitations. Not all models are suitable for every situation. Researching the specific needs of a project can guide better meter selection.

Related Posts

-

How to Choose the Right Heat Flux Meter for Your Measurement Needs

-

Top Strategies for Enhancing Efficiency with Temperature Monitoring Sensors

-

5 Compelling Reasons Why Heat Flow Meters Are Essential for Energy Efficiency in Industries

-

How to Select the Right Heat Flow Meter for Your Industrial Needs

-

How to Optimize Energy Consumption with Advanced Heat Flow Meter Technology

-

How to Choose the Right Temperature Sensor for Your Specific Application