Best Contact Temperature Sensors for Accurate Readings?

In the realm of temperature measurement, the choice of a contact temperature sensor is crucial for accuracy. Dr. Emily Chen, a leading expert in thermal instrumentation, emphasizes, “Precision in temperature sensing can greatly affect outcomes in various industries.” This statement reflects the importance of selecting the right sensor.

Contact temperature sensors, such as thermocouples and RTDs, offer reliable performance in diverse applications. However, they are not without flaws. Factors like calibration drift and environmental influence can affect readings. A sensor may excel in one scenario yet underperform in another.

Understanding these nuances is essential. It involves evaluating the sensor’s material, range, and response time. While many products promise accuracy, the selection process can be overwhelming. Recognizing potential pitfalls can lead to better decision-making. This journey towards finding the best contact temperature sensor is filled with challenges and learning opportunities.

Best Contact Temperature Sensors Overview: Types and Applications

Contact temperature sensors are essential in various applications. They come in several types, each with specific uses. Thermocouples, for example, are widely used in industrial settings. They measure a wide range of temperatures. Resistance temperature detectors (RTDs) are known for stability and precision. These sensors are ideal for scientific research.

Using contact sensors requires careful placement. The sensor must touch the surface for accurate readings. This contact can affect the temperature reading. A poor connection can lead to incorrect data. Always ensure proper calibration as well.

Tips: When selecting a sensor, consider the environment. High humidity or corrosive substances can impact performance. Evaluate the materials involved in your process. They may influence sensor choice. Small details can make a big difference.

Key Features and Specifications of High-Precision Temperature Sensors

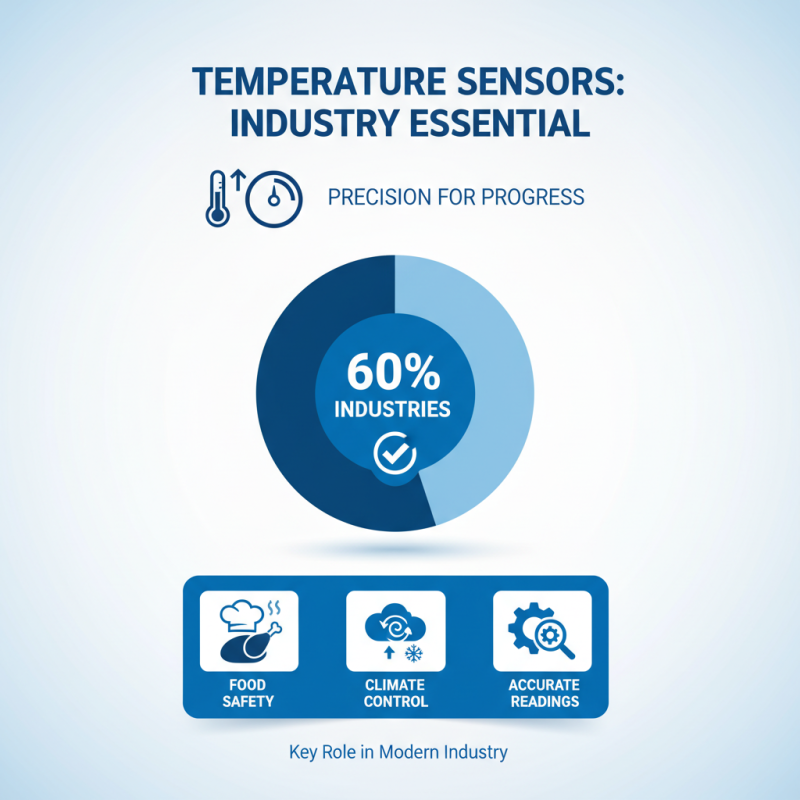

Temperature sensors play a crucial role in various industries. High-precision sensors ensure accurate readings. This accuracy is essential for processes like food safety and climate control. A recent report indicates that 60% of industries rely heavily on temperature accuracy.

Key features of high-precision sensors include sensitivity and response time. The best sensors can measure within ±0.1°C, offering reliable data. Many sensors work in extreme conditions, up to 250°C. Additionally, sensor calibration is vital. Inaccurate calibration can lead to significant errors. Nearly 25% of faults in temperature measurement systems arise from calibration issues.

Another important factor is the sensor material. Materials like stainless steel enhance durability. They resist corrosion, ensuring longevity in harsh environments. However, even the best sensors can fail. Many professionals overlook sensor positioning. Incorrect placement can result in flawed readings. Awareness of these concerns improves sensor deployment effectiveness.

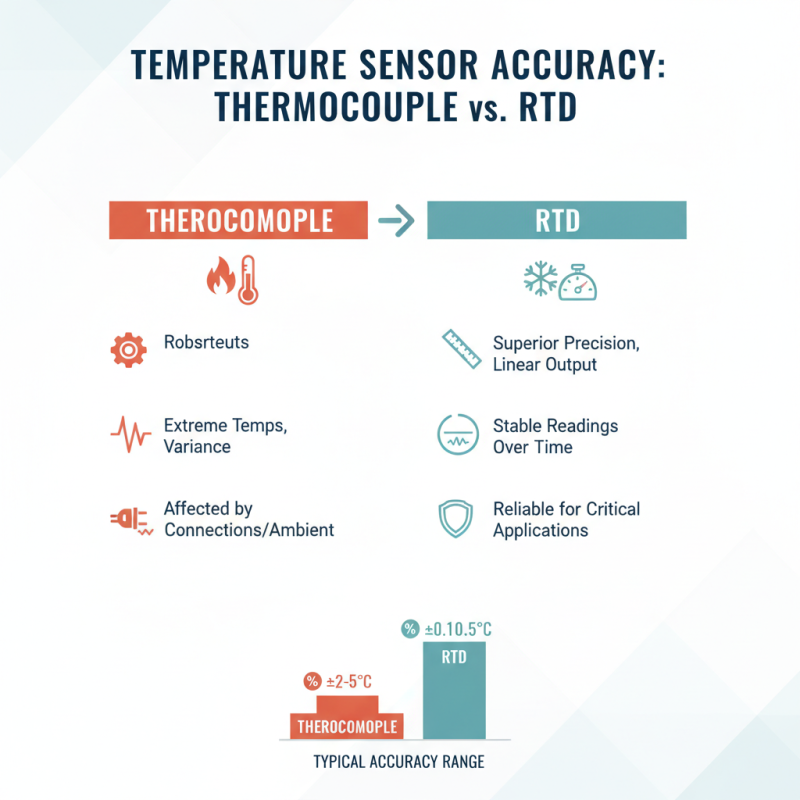

Comparative Analysis of Sensor Accuracy: Thermocouples vs. RTDs

When comparing thermocouples and RTDs, it's important to assess their accuracy in various applications. Thermocouples are widely used due to their robustness. They can function in extreme temperatures but may have variance in readings. Their accuracy could be affected by connection types or ambient conditions. RTDs, on the other hand, offer superior precision. They have a linear output and maintain stable readings over time.

Tips: Use thermocouples for high-temperature environments. They are ideal for industrial applications. For better accuracy, consider RTDs, especially in lab settings.

Different materials and construction affect these sensors. Not every thermocouple is the same. Calibration can truly impact results. An uncalibrated sensor might lead to misleading measurements. Choosing the right sensor depends on your specific needs.

Tips: Regularly check calibration to maintain accuracy. Understand your environment; don’t mix sensors without clear analysis. Consider ambient conditions as these can skew results.

Factors Influencing Sensor Performance: Environmental and Material Considerations

Temperature sensors play a crucial role in many industries. Their accuracy depends on several factors, primarily environmental conditions and the materials used in their construction. For instance, extreme temperatures can affect sensor performance. If exposed to high humidity, readings may become unreliable. Regular calibration is essential to maintain accuracy.

Material selection greatly influences sensor reliability. Different metals and polymers respond differently to heat. Some are more stable under stress, while others can degrade quickly. Conductivity and thermal mass are critical properties to consider. They determine how quickly a sensor can respond to temperature changes. Weak materials might lead to failures and inaccurate readings over time.

Another aspect is the sensor’s installation environment. Sensors placed in direct sunlight will experience different conditions than those in shaded areas. Insulation around the sensor can also affect response times. Poor installation practices can lead to errors as well. Observing these details isn’t always straightforward, but it is vital for achieving the best performance in contact temperature sensors.

Best Contact Temperature Sensors for Accurate Readings

| Sensor Type | Temperature Range (°C) | Accuracy (%) | Response Time (s) | Material Compatibility | Environmental Considerations |

|---|---|---|---|---|---|

| Thermocouple | -200 to 1260 | ±0.5 | 1 | Metals, ceramics | Suitable for high temperatures |

| Thermistor | -55 to 125 | ±0.2 | 5 | Plastics, rubber | Sensitive to moisture |

| RTD (Resistance Temperature Detector) | -200 to 850 | ±0.1 | 0.5 | Metals (usually platinum) | Excellent stability over time |

| Infrared Sensors | -50 to 300 | ±2 | <1 | None | Can be affected by dust and steam |

| Bimetallic Sensors | -30 to 500 | ±1 | 10 | Metals | Good for industrial applications |

Top Manufacturers and Market Trends in Temperature Sensor Technologies

The temperature sensor market is experiencing rapid growth. Recent reports forecast a compound annual growth rate (CAGR) of 6.7% through 2027. This growth is driven by demand across industries like automotive, HVAC, and healthcare. In these sectors, accurate readings are critical. Companies prioritize precision to enhance safety and efficiency.

The technology behind temperature sensors is evolving. Wireless sensors are gaining traction, offering advantages in flexibility and ease of installation. However, challenges remain in the form of battery life and signal interference. Moreover, many organizations struggle to integrate new sensors into existing systems. This integration can lead to incomplete data and unreliable readings if not addressed.

As environmental concerns rise, green technologies will influence future designs. Sensors capable of operating in extreme conditions are also in demand. Market reports indicate that the industrial segment held the largest share in recent years. Yet, some manufacturers face challenges in scaling their production lines. Balancing quality and cost remains a significant hurdle in this competitive landscape.

Best Contact Temperature Sensors for Accurate Readings

Related Posts

-

2025 Top 10 Temperature Sensors: The Best Choices for Precision and Performance

-

Top 10 Temperature Probe Sensors for Accurate Cooking and Laboratory Use

-

2025 Top Contact Temperature Sensor Trends and Innovations You Need to Know

-

Top 10 Heat Flux Transducers You Need to Know About?

-

Ultimate Guide to Mastering Thermal Conductivity Sensors for Enhanced Performance

-

How to Choose the Right Temperature Sensor for Your Specific Application